How to Prolong the Life of Your Laser Tube

The laser tube is one of the most, if not the most important part of a laser machine. It is responsible for emitting a high-powered laser beam, to be reflected off a series of mirrors and finally through a lens onto the material you are looking to process. So it's crucial to do all you can to keep your laser tube in tip-top working condition if you want to ensure the quality of your work.

In this blog post, we'll go over some of the common questions surrounding these important components and most importantly how you can extend the life of your co2 laser tube.

What is a glass laser tube?

A glass co2 laser tube is a device that uses compressed gases and a high voltage current to produce a laser beam. The gas is electrically charged to pass through the glass chamber, which amplifies the light waves and produces a powerful laser beam. These laser tubes are used in a variety of applications, including engraving, cutting, and marking.

What’s the difference between glass and metal co2 laser tubes?

There are 2 main types of co2 laser sources. DC laser source (Glass), and RF laser source (Metal). The difference between these components essentially comes down to how they convert the power source into a light beam for the application of cutting, engraving and marking. Glass CO2 laser tubes rely on a direct current, whilst metallic laser tubes use radio frequency.

Glass laser tube

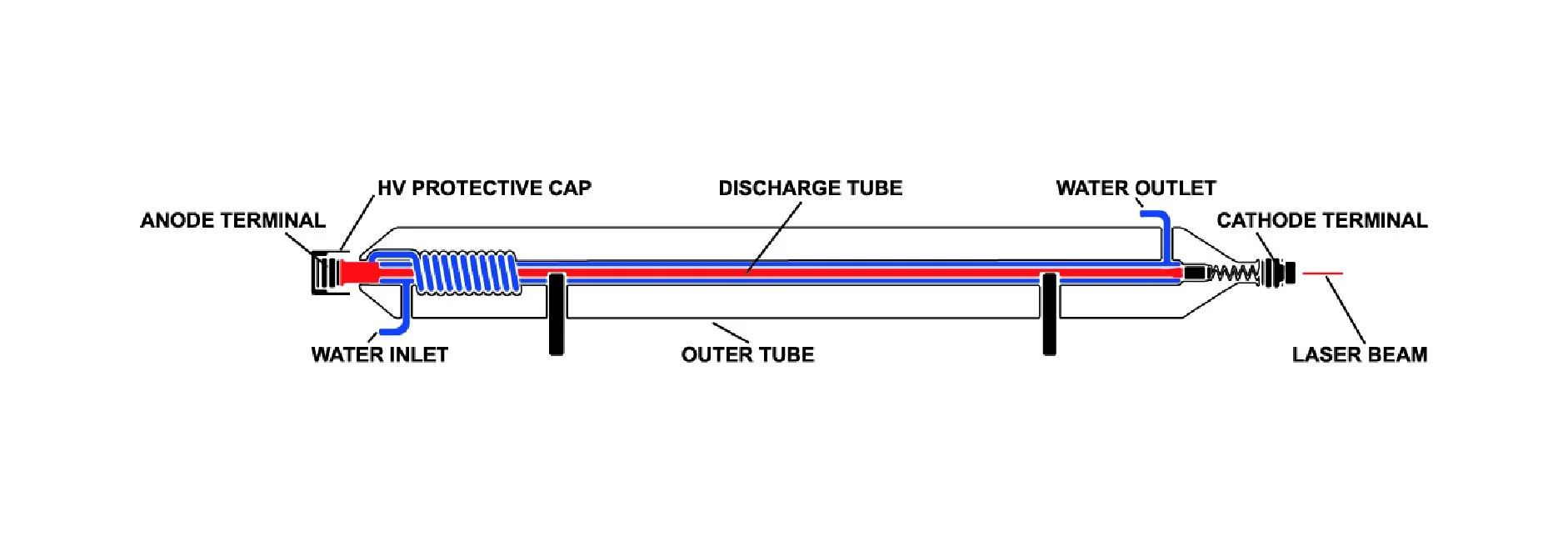

DC laser tubes are typically contained within a glass laser tube. Inside the glass tube of the DC laser, there is a mixture of different gases: Nitrogen, carbon dioxide, helium, and sometimes hydrogen and xenon, as well as two electrodes; The cathode and the anode. The cathode is located at one end of the tube and emits electrons into the gas-filled chamber, and the anode is located at the other end of the tube and collects these emitted electrons.

This compressed gas chamber is activated by the Power supply unit feeding the cathode using varying high voltage currents to activate the gases and produce the laser beam through the lens in the end of the laser tube, directing it at the mirrors.

Naturally during this reaction the laser machine produces a lot of heat. So to prevent the gas chamber from overheating, there is another outer layer surrounding it. This space is full of circulating water which absorbs the machine's heat (Usually deionised or demineralised to help prevent scaling and rust and keep temperatures down). Typically this is done with a chiller unit which, as well as circulating the water, also cools the water to keep the laser operating within the appropriate temperature range for maximum efficiency.

Metal laser tubes

The alternative to DC laser tubes as mentioned above are RF lasers.

RF lasers are supplied with energy from power radiated by antennas. As the excitation frequency is in the range of the radio frequencies. The radio frequency activates the nitrogen molecules in order to produce the laser beam.

RF lasers can be operated at much higher repetition rates (measured by the number of pulses delivered in one second) than DC lasers. This enables fast engraving/marking, where each contrasting pixel requires a single laser pulse.

If the laser resonator is designed as aluminium-oxide-ceramic it has the benefit of being able to be pumped with low loss. As the antennas are outside the resonator, there are no feedthroughs in the resonator that are problematic for the gases to be able to escape as easily and therefore making this method capable of an extended gas life.

Why are laser tubes in laser cutters consumables?

Laser tubes are consumables in laser cutters because they eventually run out of gas. DC laser tubes typically last around 2-3 years, whereas RF laser tubes can last around 6 years..

As you use your laser machine, over time the co2 gases in the tube mix, converting the CO2 which contains one atom of carbon and two atoms of oxygen into CO which has one carbon and one oxygen atom.

The laser essentially needs the oxygen atoms to help produce the laser beam.

As these gases convert over a period of usage, the laser beam becomes less effective, resulting in poorer processing performance.

Eventually, the laser tube will no longer be able to create a usable beam and will need to be replaced or re-gassed

How to prolong the life of your laser tube?

It's no secret that the life of your laser tube is a critical factor in the overall performance of your laser machine. Replacing a laser tube in your laser cutter can also be inconvenient, costly and time-consuming. So it's important to do everything you can to prolong the life of your current tube.

Maintenance of the optical path

It is vital to keep your laser mirrors clean as well as your focal lens. Even on a perfectly aligned and cleaned optical path, it is not uncommon to lose between 10-15% of the power of your laser, and dirty optics will increase this significantly. You should be checking and cleaning your mirrors at least on a weekly basis and your lens should be cleaned on a daily basis. Cleaning more regularly when processing materials that release large amounts of debris when engraving/cutting such as acrylic and wood is recommended.

When the machine's optics are dirty, you might find you are either increasing power or decreasing speed to keep up the same cutting efficiency. Running the laser under these suboptimal conditions means it will have to work harder and for longer than necessary and cause your mirrors and lens damage which will then need to be replaced as they would no longer efficiently reflect the laser beam.

Regularly monitor your tubes power output

Over time, all tubes will wear out and the power they produce will decrease. If you're serious about laser cutting, buy yourself a laser power meter reader and check the output right out of the tube.

With any luck, your laser tube will last you a few years. But as with everything else in life, there are no guarantees! Once it has lost around 25-30% of the Rated Power (the actual percentage depends on application and throughput) then it's time to start planning a replacement.

At Focused Laser Systems all our technicians are equipped with a top of the line laser power meter to accurately gauge the wattage left in your laser tube, and help to diagnose the health of your laser tube before suggesting a replacement.

Fit an ammeter

It is highly recommended that you have an ammeter fitted to your laser machine if it doesn't have one already. This will allow you to make sure you're not overdriving your laser tube beyond the manufacturer's recommended maximum operating current, as this will prematurely age your tube and shorten its working life.

Pushing too much current through the laser tube will cause the tube to generate more power in the short term, but this naturally will lead to the life of the laser tube being dramatically reduced.

This extra power will also generate more heat, which in turn could damage the glass surrounds of the laser tube housing, causing extra wear to the optics, and will make the chiller unit have to work harder to keep it cool.

This also brings into the mix, the possibility that the chiller unit now isn’t capable of efficiently cooling down the extra heat generated by overdriving the power supply unit to make the laser tube generate more power and so has the potential to damage not only the laser tube but the chilling unit and optics.

Laser cooling system

If possible, it is best to use a fully enclosed cooler or chiller unit in order to measure both temperature and water flow. This unit should not only give an alarm if there is a problem but stop the laser from operating without sufficient cooling, insufficient water flow, or even if you just forgot to turn your chiller unit on. This would help to prevent any further damage to your laser tube caused by malfunctioning equipment.

It only takes a couple of minutes to ruin a tube through overheating. The optimal temperature for a laser tube is between 15°c and 25°c; however, as the temperature rises, the efficiency of the tubes starts to drop which then lowers its power output.

Find a supplier you can trust

If you are looking for a replacement tube make sure you buy a quality brand from a trusted supplier.

RECI laser tubes could be described as the Rolls Royce of manufacturers, providing both performance, reliability, and affordability, followed closely by EFR.

The 80w RECI laser tube is the lowest wattage of this model.

If you, however, require a lower-watt tube, we would recommend the 60w EFR laser tube.

The majority of laser tubes are manufactured in China. When buying directly from China for laser tube replacements, please do your research and buy from reputable suppliers. Sadly there has recently been a wave of counterfeit laser tubes being sold.

It is also worth taking into consideration the cost attached to returning a laser tube when shipping internationally. So please make sure you purchase the correct tube for your make and model of co2 laser and you are confident enough to install and calibrate your own laser tube, otherwise we would recommend reaching out to a laser machine engineer.

Ideally, we would always recommend purchasing from UK-based stockists to provide you with peace of mind, warranty, and a point of contact should you run into any issues.

When should a laser tube be replaced?

The main indications that a laser tube needs to be replace:

One sign is poor cutting performance. If you notice that your cuts aren't as clean as they used to be or you’re having to use more power than usual to cut through materials then it may be time to book in a service which includes a laser tube health check, so you can be sure this is the cause before going ahead and replacing the tube.

Another indication is that the light beam becomes dimmer and the colours appear less vibrant. As a laser tube wears down, it becomes less effective at creating a powerful beam of light, which results in poorer processing performance. Eventually, the beam will no longer be bright enough to cut through materials effectively.

With a brand like Reci, you can typically expect the laser tube to last up to 10,000 hours with proper care and maintenance.

Conclusion

We hope this blog post has been helpful and going forwards you have a better understanding of how to keep your laser tube in peak optimal working conditions and recognise when it’s time for a replacement.

As always if you have any questions or would like professional advice on maintaining your laser cutter, whether that means replacing tubes or taking other steps to keep it running optimally please don't hesitate to contact us.