CO2 Laser Training

Unlock New Possibilities With Our Laser Cutting Machine Training Services.

Is Adobe Illustrator or Lightburn giving you headaches? Need help getting your laser machine software to behave? Or maybe you're just trying to get those perfect laser cutting and engraving parameters for a particular project?

At Focused Laser Systems, our technicians provide comprehensive 1:1 training, both in person and remotely, to help you master your laser cutter and its associated software. We understand that each customer's needs are unique, and we are here to cater to them, regardless of your brand of laser cutter.

Transform Your Ideas into Reality.

Let's unlock the full potential of your laser system! Please fill out the form below. Our friendly team of technicians are ready to assist you with any questions and schedule your 1:1 training session. Alternatively, call or WhatsApp us on 01271 626 406 for a quick response.

FAQ's About Our CO2 Laser Training

Curious about our laser cutter training? We've got answers! Check out our responses to common questions, or feel free to contact our technicians directly. We're happy to help!

-

We provide training for a wide range of laser cutter brands. While we can't give an exhaustive list, some of the common brands we work with include:

Boxford

CTR Laser Cutters

Epilog Laser

HPC Laser / Laserscript

Lotus / Blu series

Mantech / LaserTech

Burghmann

Omtech

Opus

Thunder Laser

Universal Laser Systems

-

Our training covers various design and operating software commonly used with CO2 laser cutters, such as Adobe Illustrator, CorelDRAW, LightBurn, RDWorks, CorelDraw, and software for specific laser cutter brands.

-

Training sessions typically cover:

Machine Operation: Basic setup, safety procedures, loading materials, controlling the laser, maintenance, and troubleshooting.

Software Operation: Designing for laser cutting and engraving, file preparation, optimising settings for different materials, and advanced techniques.

Material Selection and Preparation: Understanding material properties, choosing suitable materials for your projects, and preparing materials for optimal results.

Project-Specific Guidance:

We can provide tailored training based on your specific projects and goals, helping you achieve the desired outcomes.

-

1:1 training offers personalised attention and allows the trainer to focus on your specific needs and skill level. You can ask questions, get immediate feedback, and learn at your own pace.

-

Yes, we provide on-site training at your location, ensuring you get hands-on experience with your own laser cutter and software setup.

-

Absolutely! We also offer remote training via video conferencing and remote computer access, allowing you to learn from the comfort of your workspace. We find that the software training is done well remotely, but most people prefer the machine training to be on-site as it's easier to demonstrate. If you let us know what you’d like to achieve with the training session we will be able to advise the type of training that will suit your requirements.

-

The duration of training sessions varies depending on your needs and prior experience. We offer flexible scheduling options to accommodate your busy schedule. As a rough guide, our on-site training sessions usually last around half a day or so and come to a natural conclusion when you feel confident enough to proceed on your own. And our remote training sessions are booked in 1 hour slots.

-

The cost of training varies based on factors such as the duration, location (on-site or remote), and specific training needs. Please get in touch with us for a personalised quote.

-

Yes, we provide ongoing support and assistance even after the training is complete.

Additionally, we also offer a range of service packages that include an annual service as standard, remote technical support, extensive discounts on replacement parts and callouts from our engineers.

You can contact us with any questions or issues that arise.

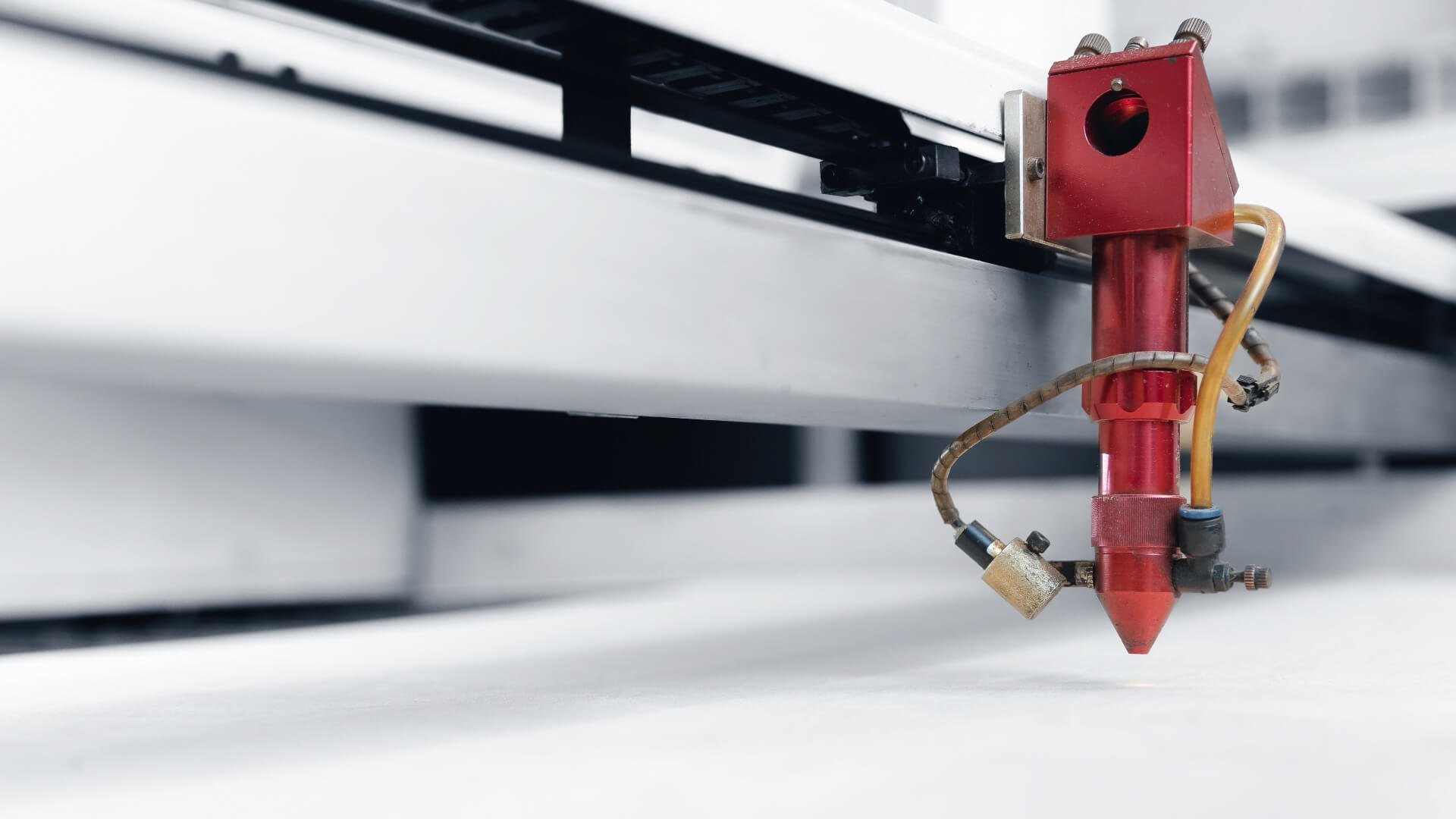

Processing Tips.

Tips for maximising your laser machine: achieve precise engraving, clean cutting edges, reduce processing time and more.